ALT Dura Products

Engineered Solutions » Adhesiveless Lamination Technology (ALT) » ALT Dura Products

- ALT Dura™ Products

Fralock ALT Dura™ Products are specialty components made with polyimide film that is laminated without adhesives to produce a robust monolithic material that is extremely durable and resistant to delamination. This material is highly suited for use in demanding environments for critical applications and can operate for extended lengths of time.

These products are used for applications in industries such as aerospace, space, military, defense, semiconductor, medical, industrial, and energy.

ALT Dura™ Product Types

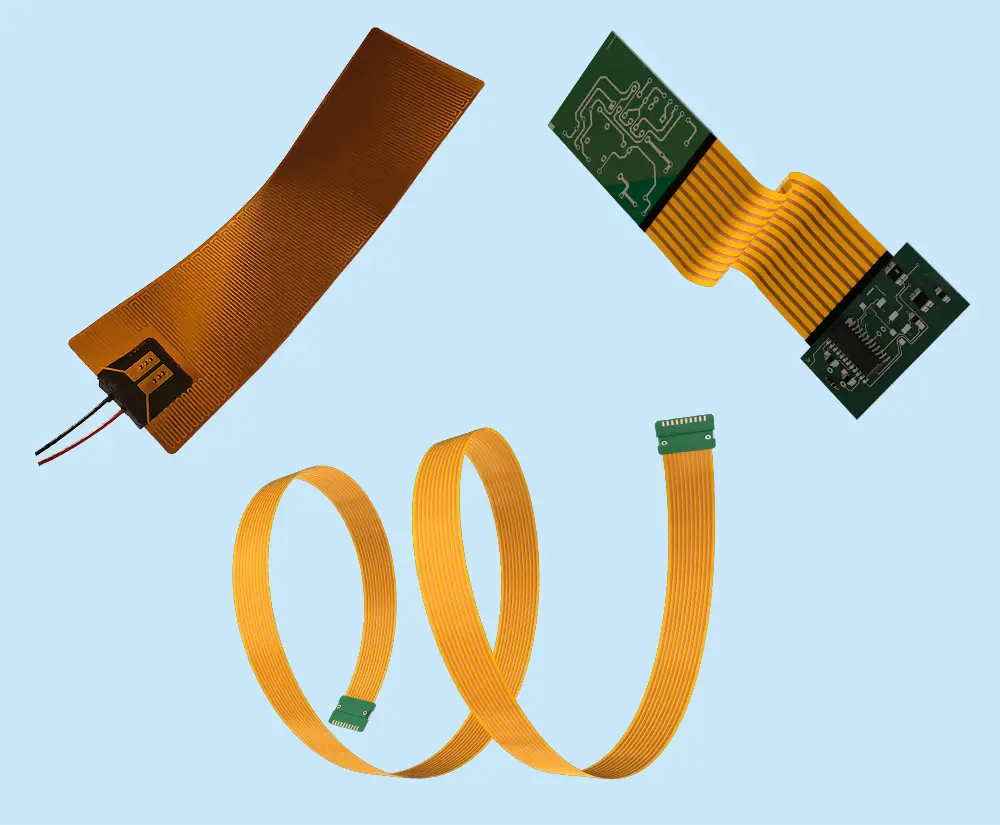

Fralock manufactures several types of products made with Adhesiveless Lamination Technology (ALT)™ to satisfy requirements of your unique applications. These include flexible interconnects (flex and rigid-flex circuits), flexible polyimide heaters, and thin, flexible grounding straps.

Flexible and Rigid-Flex Circuits and Heaters

ALT Dura™ flex circuits fully encapsulate the traces with polyimide to protect the metal foil from environmental damage and degradation.

Products include flex and rigid-flex circuits, harnesses, and heaters that can withstand delamination under stresses such as hard creasing, repetitive flex cycles, high heat, and cryogenic environments.

ALT Dura™ flex circuit products offer:

- Superior resistance to trace swimming under high temperatures

- 30% reduction in mass compared with traditional adhesive-based flex products

- Wide operational temperature range, from -269°C to 250°C (-452°F to 482°F)

- Highest Power Watt Density to 200W/in2

- Glass transition temperature (Tg) starting ~220°C (428°F) to 250°C

- All-polyimide extended flex circuits - up to 50 ft or more

- All-polyimide circuit boards

- Flexible board-to-board connectors - rigid-flex design allows multiple layers of polyimide and metallization

- Flex-to-board connectors, BGA and LGA sockets - provides high-reliability and performance in molding operations

ALT Dura™ Heaters for Semiconductor Wafer Manufacturing

Fralock ALT Dura™ wafer heaters offer benefits over other heater types used in wafer processing such as FEP polyimide heaters:

- Higher maximum power density and operating temperature

- Faster response times

- Maximum power density at least 3 times that of Teflon heaters

- Repeated thermal cycling without damage and continues to perform without any notable degradation

- Withstands high radiation environments

- Parts that are heat-formed maintain shape

- Lower outgassing

Metal-Encapsulated ALT Dura™ Heaters

Fralock provides ALT Dura™ polyimide heaters that are encapsulated with metal (aluminum, copper, or stainless steel).

These heaters are ideal for applications that require the heat to be dissipated in extreme environments such as space or semiconductor manufacturing.

In use cases where a directional heater is needed (heat radiated from one side only), a layer of DuPont™ Cirlex® can be applied inside the metal casing to block heat from the opposing side. Cirlex® is an excellent heat blocker and can be bonded with Adhesiveless Lamination Technology (ALT)™

Fralock ALT Dura™ grounding straps are ultra-thin, flexible, and can bend, fold, and twist. They are designed for exceptional performance in a variety of demanding applications.

These grounding straps use copper conductors and are laminated with polyimide. They are ideal for configuration in equipment that requires a low-profile, flexibility, high amp capacity, and low mass, such as aircraft engines, missiles, spacecraft, test assembly stations, and more.

- Reduced mass

- 130 Amp capacity

- Flat, low profile - as thin as 0.006”

- Complex routing made easy - improves assembly efficiency, easily routes around corners and through tight spaces

- Temperature range: -269°C to 300°C (-452°F to 572°F)

- Adhesiveless bonding (adhesive bonding available)

- Withstands creasing and repetitive flex cycling even at high voltages

- Shock and vibration resistant

- Longer lifetime than traditional wire construction

- Dimensions: Up to 110”L (279.4 cm). For lengths over 110” please consult with Fralock

View/Download Literature