Aerospace And Defense

Industries » Aerospace And Defense

- AEROSPACE & DEFENSE CAPABILITIES

The development and engineering of spacecraft, satellites, aircraft, and missiles is a challenging endeavor. Rigorous requirements in harsh environments require thoughtful, calculated design and precise engineering. Each component must be designed to exact specification to satisfy multiple requirements for these critical applications.

The development and engineering of spacecraft, satellites, aircraft, and missiles is a challenging endeavor. Rigorous requirements in harsh environments require thoughtful, calculated design and precise engineering. Each component must be designed to exact specification to satisfy multiple requirements for these critical applications.

As an AS9100:2015 certified and ITAR registered company, Fralock ‘s engineers work as an extension of your engineering team to provide optimal solutions for aerospace and defense applications. With over 55 years of product design, specialty material and process knowledge, we are space-qualified and experts at helping you reach your design and production goals.

Fralock’s Technical Knowledge™ (FTK) allows us to combine seemingly incompatible materials for mission-critical applications.

Our flexible circuits and heaters can be made using Fralock’s Adhesiveless Lamination Technology (ALT)™ for fully-encapsulated flex circuits and cables, sealing the traces from environmental damage. This type of bonded material uses no adhesives and provides superior performance over adhesive-based products, which tend to degrade under extreme environmental and chemical stressors.

- AEROSPACE & DEFENSE CAPABILITIES

As an AS-9100 and ITAR registered company, Fralock ‘s engineers work as an extension of your engineering team to create optimal solutions for aerospace and defense applications. With over 50 years of product design, specialty material and process knowledge, we are experts at first-class engineered solutions.

Fralock’s Technical Knowledge™ (FTK) allows us to combine seemingly incompatible materials for mission-critical applications. Our pioneered adhesiveless lamination enables production of are fully- encapsulated flex circuits and cables, sealing the traces from environmental damage. This type of bonded material provides superior performance over using adhesives, which tend to degrade under extreme environmental and chemical stressors.

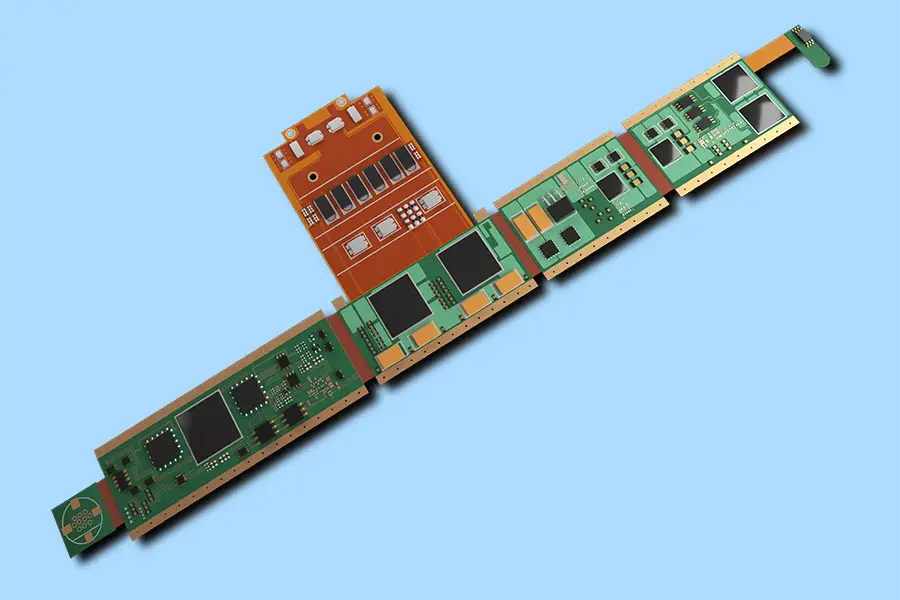

Robust Encapsulated Polyimide Flat Flex Cables

Flex Circuits for Defense, Space, and Satellite Applications

Our flexible circuits and heaters can be manufactured using our Adhesiveless Lamination Technology (ALT)™ or with adhesives.

Flex Circuits for Defense

Designed to endure extreme temperatures, shock, and vibration that occurs in military environments, flex circuits used in defense applications are essential for providing lightweight, compact solutions for the miniaturization of equipment, allowing for efficient and mobile systems.

Flex Circuits for Space

Flex circuits for space applications are engineered to meet the stringent requirements of wide temperature ranges, high radiation levels, and vacuum environments. Their flexibility and durability ensure electrical integrity despite the mechanical stresses experienced during launch and operation in space. Their low mass also helps to optimize the payload capacity and efficiency of spacecraft.

Flex Circuits for Satellites

Due to their ability to conform to tight spaces and curved surfaces, flex circuits and heaters are ideal for satellites due to the compact and irregular shapes of their assemblies. Their high reliability and performance and reduced weight ensure that satellite systems can operate without failure over long durations in the harsh environment of space.

Advanced Heater Technology

Fralock delivers cutting-edge heater technology designed to meet the rigorous demands of the aerospace and defense sectors. Our solutions combine precision engineering with advanced materials to ensure reliable thermal performance in the most challenging environments.

Fralock heaters provide exceptional thermal uniformity and can be customized with multiple heating zones for precise temperature control, enabling optimized performance for specialized applications.

Flexible Etched Foil Polyimide Heaters

- Low Mass: Lightweight design minimizes system weight, critical for aerospace applications.

- Low-Profile Designs: Perfect for tight spaces where compact components are essential.

- Large Area Coverage: Uniform heating across extensive surfaces for critical systems.

- Wrap-Around Designs: Flexible configurations that conform to complex shapes.

Aluminum Nitride (AlN) Ceramic Heaters

- High Watt Density: Capable of generating significant heat output for demanding applications.

- Rapid Thermal Cycling: Quick temperature adjustments for processes requiring agility and precision.

- Multiple Heating Zones: from 1 to 25+ zones for precise control and thermal uniformity

- Wide Range of Shapes and Sizes: From a few millimeters to 15 inches

Low Mass Grounding Solutions - Flexible Grounding Straps

Fralock provides flexible, ultra-thin grounding straps engineered for outstanding performance in even the most challenging aerospace and defense environments. Designed to bend, fold, and twist with ease, these straps offer unmatched versatility and reliability.

Featuring a low-profile design, our grounding straps are constructed with copper-polyimide lamination, using either adhesive-based bonding or our proprietary Adhesiveless Lamination Technology (ALT)™. Capable of handling up to 130 amps, these solutions deliver superior electrical performance while maintaining a lightweight and compact form.

Specialty Engineered Materials & Advanced Component Solutions

Fralock’s engineered material solutions are tailored to optimize performance, reliability, and efficiency. Leveraging a wide range of materials sourced from top-tier suppliers, we ensure compliance with rigorous quality requirements for government and commercial contracts. Our capabilities include advanced material selection and the development of custom laminates that outperform existing technologies.

- Thermal Management: Materials for efficient heat transfer, blocking, spreading, and thermal uniformity, protecting sensitive components from overheating or cold environments.

- EMI/RFI Shielding: Shielding components that prevent electromagnetic and radio frequency interference, ensuring the integrity of critical systems and devices.

- Vibration & Shock Dampening: Materials that reduce mechanical vibrations and absorb shock, extending the lifespan and performance of sensitive equipment.

- Electrical Insulation: A wide variety of materials tailored to deliver exceptional insulation, ensuring safety and preventing electrical faults in high-performance systems.

- Sealing & Gaskets: Reliable sealing solutions for high-pressure, high-temperature, and corrosive environments, ensuring system integrity.

- Fastening & Bonding: Pressure-sensitive tapes for securing components or wiring, offering a lightweight and flexible alternative to traditional fasteners.

- Radiation Resistance: Fralock offers materials with excellent resistance to high-energy radiation such as DuPont™ Kapton® Films.

- Structural Parts: Advanced materials like DuPont™ Cirlex® provide lightweight, durable, and high-precision components for demanding applications in severe environments.

Advanced Structural Ceramics

We provide advanced ceramics for a wide variety of aerospace and defense applications, such as fuel and propulsion systems, optical devices, microwave applications, and more. Our technology ensures tight tolerances and precision manufacturing for demanding requirements.

- Silicon Carbide

- Aluminum Oxide

- Zerodur

- Aluminum Nitride (AlN)

- Sapphire

- Quartz

Cirlex® & White Kapton

Fralock manufactures DuPontTM Cirlex® for use in multiple applications. Cirlex® is a versatile polyimide that is laminated without adhesives and custom fabricated into many shapes and sizes. Highly machinable, with high tolerance of thermal, physical and chemical properties, it can be used in applications such as flex circuit stiffeners or thermal blockers, flex-to-board connectors, thermal and electrical interface applications, thrust washers, shims and spacers.

White Kapton® is a high emissivity Kapton film widely used for space applications, and can be metalized for use in spacecraft and aircraft. Fralock provides white Kapton® film and tape fabricated to your specifications.

Fralock HEK pressure-sensitive adhesive tape made with White Kapton®.

With extensive experience in product design, material selection, and process knowledge, Fralock’s engineering team can help you overcome challenges and provide superior components to enhance performance in aircraft, spacecraft, satellites, solar arrays for space, and missiles.

Solutions Include:

- Flat Flex Cables

- Flex/Rigid-Flex Circuits

- Antenna components

- Solar Arrays

- Solar Array Components

- Zerodur glass optics

- Thermal shock resistant ceramic parts made from aluminum nitride

- Ceramic fluid atomizers and nozzles

- Heaters

- Diode Boards

- Films/Specialty Tapes

- Mechanical Seals

- Foams/Rubbers

- Thin Film Ceramic Substrate RF Circuits

- Thick film Mo/Mn metallization on Alumina and Aluminum Nitride

- EMI, RFI Shieldin

- Flat Flex Cables

- Flex/Rigid-Flex Circuits

- Antenna components

- Solar Arrays

- Solar Array Components

- EMI, RFI Shields

- Heaters

- Diode Boards

- Films/Specialty Tapes

- Mechanical Seals

- Foams/Rubbers

- CIRLEX

As the sole manufacturer for DuPontTM Cirlex®, Fralock provides custom fabrications of this versatile polyimide. With high tolerance of thermal, physical and chemical properties, it can be used in applications such as flex circuits, flex-to-board connectors, thermal and electrical interface, thrust washers, shims and spacers.

With over 50 years of product design, material and process knowledge, Fralock’s engineering team can overcome your challenges for optimal performance for aircraft, spacecraft, satellites, and space-based solar arrays.

- Flat Flex Cables

- Flex/Rigid-Flex Circuits

- Antenna components

- Solar Arrays

- Solar Array Components

- EMI, RFI Shields

- Heaters

- Diode Boards

- Films/Specialty Tapes

- Mechanical Seals

- Foams/Rubbers

- Flat Flex Cables

- Flex/Rigid-Flex Circuits

- Antenna components

- Solar Arrays

- Solar Array Components

- EMI, RFI Shields

- Heaters

- Diode Boards

- Films/Specialty Tapes

- Mechanical Seals

- Foams/Rubbers